I was contracted by Sonoran Rovers, a Land Rover shop specializing in custom overlanding builds, to develop an install kit for the Alu-Cab Alu-Cabin and the Defender 130 chassis. The first of it’s kind, Sonoran Rovers had already done some initial R&D and fit checks to determine that the overall dimensions would work. I was contracted to engineer the necessary components and assembly methodology to make this a repeatable process and standard offering for Sonoran Rovers’ clientele.

Together with Sonoran Rovers, we defined cost targets and key requirements. Alu-Cab’s Alu-Cabin is marketed towards modern 5.5 and 6.5 foot trucks (think Tacoma, Tundra, F-150, Ram, etc…) and utilizes t-slot profiles in the base of the Alu-Cabin to interface with the accessory bedrails on these trucks. We wanted our kit to be just as minimally invasive and removable should the owner opt to remove it for a season or particular trip.

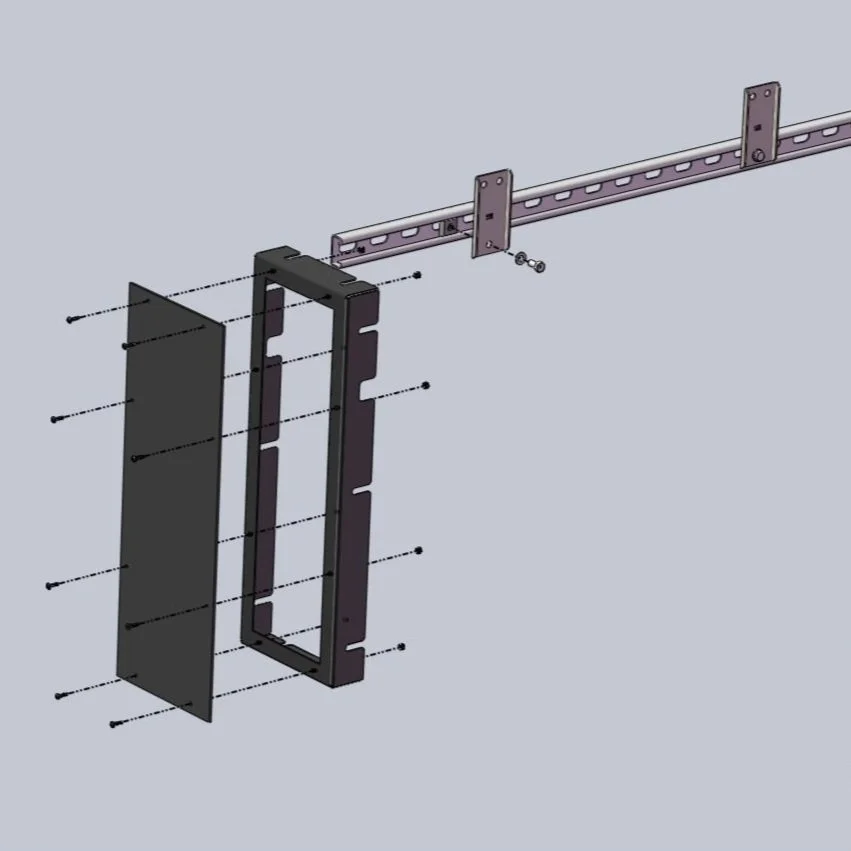

A mixture of traditional hand measurement techniques and 3D scanning (near the tailgate region in particular) were utilized to define the bedrail and tailgate hardpoints. CAD (SolidWorks) was used to design the necessary components and conduct initial load simulations on key structural components. The kit components featured a mixture of off-the-shelf hardware and extrusions, custom sheet metal and machined components, and laser cut gaskets.

Prototype parts were subjected to shakedown and real world tests to validate the designs before committing to initial production runs. Vibration isolation and panel gap / fitment optimization really benefited from these early prototype and fit checks.

Sonoran Rovers now offers these exclusive, proprietary Alu-Cabin x Defender 130 installs to their customers and spec builds. The engineering package facilitates repeatability, follow up orders and their ownership of the design and the ability to own changes moving forward.