-

The Project

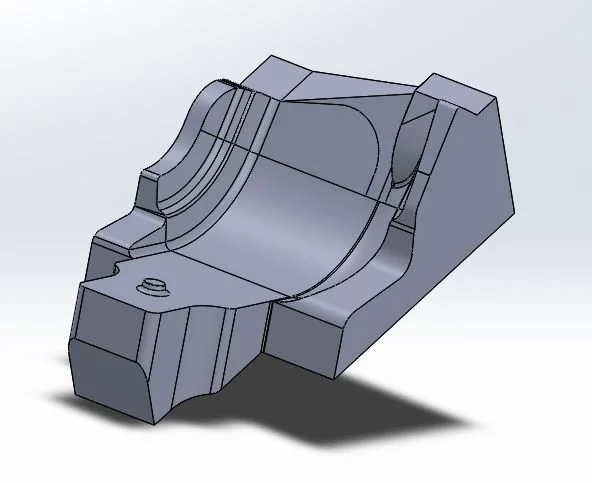

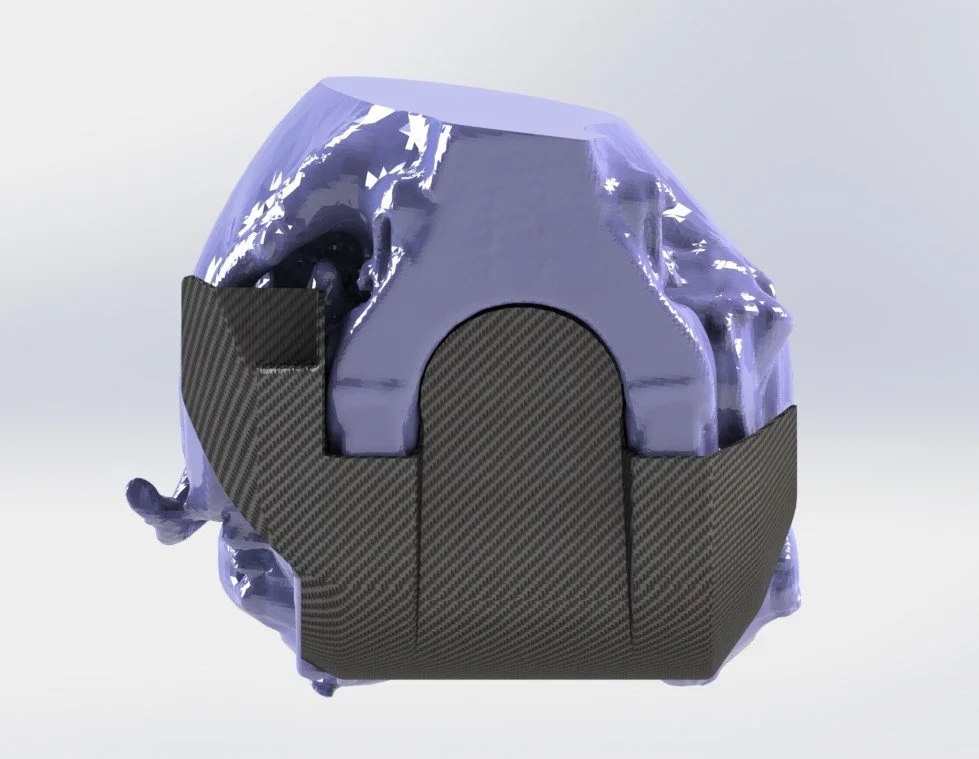

The client produces high end aftermarket carbon fiber accessories for the power sports market. Presidio Design and Engineering was engaged to develop a 3D CAD design processes to speed up new product development and improve production tooling (quality and tool life).

-

The Process

Presidio Design and Engineering worked with the client to understand project requirements and develop a comprehensive proposal. We developed an efficient product design process utilizing 3D scanning technologies and SolidWorks 3D CAD software. Fully fledged CAD models were then used to rapidly develop molds and tooling. All without the need for iterative and expensive physical prototypes.

Tools deployed include: 3D Scanning, CAD (SolidWorks), CNC machining

-

The Results

Together with the client we were able to develop new products much faster than before (time to market was crucial for the client) and with full CAD models for all products we were able to have tooling CNC machined which greatly improved the accuracy and lifespan of the tooling. The client eventually grew confident enough with the design and production tool process that they now handle everything in-house.